Hard hats are essential safety gear in many industries. They protect workers from potential head injuries caused by falling objects, electrical hazards, and other workplace dangers. While many people may presume that hard hats arrive ready to use, this isn’t always the case. Understanding how to assemble a hard hat properly is crucial for ensuring maximum protection. This guide will walk you how to put a hard hat together effectively.

Understanding Hard Hats and Their Components

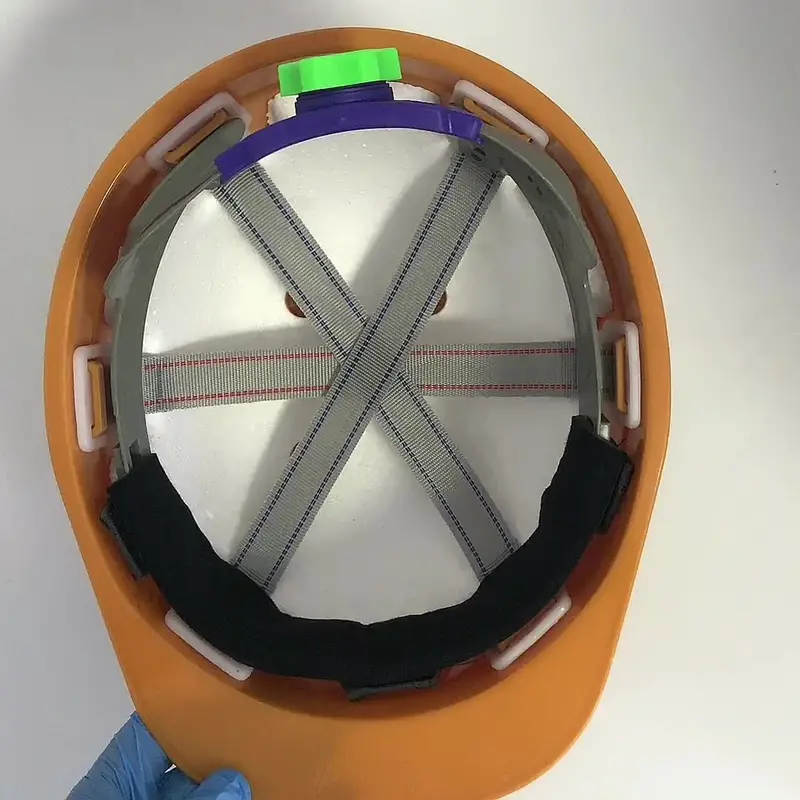

Before diving into assembly, it’s important to recognize the components of a hard hat. Hard hats consist of an outer shell and an inner suspension system. The outer shell is designed to absorb the force of impact. The inner suspension system helps distribute that impact across the wearer’s head. Usually made of durable materials, both components are vital for safety.

The Outer Shell

The outer shell is the hard cover that protects the head. It is commonly made of high-density polyethylene (HDPE) or fiberglass. These materials are chosen for their durability and impact resistance. Each hard hat is also rated to meet specific safety standards, such as ANSI Z89.1 in the U.S. Knowing this can help you choose the right hard hat for your work environment.

The Inner Suspension System

The inner suspension system generally consists of a series of straps and a plastic cradle. This design holds the hard hat securely on the head. A proper fit is crucial, as it ensures the hard hat will stay in place during movement. This suspension system can often be adjusted for different head shapes and sizes. Familiarizing yourself with the inner system is a key step in assembly.

Step-by-Step Assembly Process

Now that you understand the components, let’s move to the assembly process. First, gather all necessary components and tools. Since hard hats often have unique designs, refer to the manufacturer’s guidelines. Check whether any accessories are included, such as chin straps or earmuff attachments. Knowing what you have can simplify assembly.

Step One: Prepare the Outer Shell

Begin by inspecting the outer shell carefully. Look for any signs of damage or defects. A damaged outer shell may compromise safety, so discard it if necessary. If everything looks good, then proceed to the next step. Proper validations ensure that the outer shell will perform effectively in a work situation.

Step Two: Attach the Suspension System

The next step involves placing the suspension system inside the outer shell. Most systems have clear indicators for positioning. Align the suspension correctly, ensuring that it sits securely within the shell. The straps usually have slots or hooks designed for attachment. See that these are aligned for a secure fit.

Step Three: Adjust for Fit

Once the suspension system is in place, adjust it for your comfort. Each hard hat features adjustment mechanisms, such as sliders or ratchets. These allow for customized sizing based on head measurements. A well-fitted hard hat should sit snugly but not uncomfortably. The goal is to ensure it stays in place without causing any discomfort.

Step Four: Secure Additional Accessories

If your hard hat incorporates accessories, now is the time to attach them. Accessories may include face shields, earmuffs, or lights, depending on your work requirements. Each accessory will usually have specific instructions for attachment. Follow these closely to ensure they fit securely and maintain safety.

Step Five: Final Inspection

Once everything is assembled, conduct a final inspection of the hard hat. Check that all components are securely attached, and test the fit one last time. The hard hat should sit comfortably on your head without any excessive movement. If you notice any issues, adjustments should be made immediately. Your safety is paramount, and inspections contribute to a safe work environment.、

Maintaining Your Hard Hat

Proper maintenance extends the life of your hard hat and preserves its safety features. It should always be cleaned after use, particularly in harsh environments. Dirt, dust, and chemicals can weaken materials over time. A gentle wash with soap and water usually suffices. Always follow manufacturer instructions for cleaning and maintaining your hard hat.

Cleaning Your Hard Hat

To clean the outer shell, start by removing any attachments. Use a soft cloth and mild soap to wipe it down thoroughly. Avoid using harsh chemicals or solvents that could damage the surface. Pay special attention to tough spots or residues. A clean hard hat not only looks better but also performs better.

Checking for Damage

Regularly check your hard hat for wear and tear. Look for cracks, dents, or faded colors that may indicate structural weaknesses. Colors may fade due to sun exposure, which can weaken the shell’s integrity. If you identify any significant damage, replace the hard hat immediately. Do not compromise on safety; always prioritize a functional hard hat.

Recognizing When to Replace Your Hard Hat

Even with regular maintenance, a hard hat won’t last forever. Many manufacturers recommend replacing hard hats every five years, but this can vary. It’s essential to consider the work conditions and use frequency as well. Frequent impacts or exposure to harsh environments may necessitate more frequent replacements.

Signs of Wear and Tear

As mentioned, obvious signs such as cracks or dents are a red flag. Additionally, look for any components that no longer fit properly, such as the suspension. If any part becomes loose or detached, it may compromise the hard hat’s safety. Regular assessments will help identify any necessary replacements.

Manufacturer Guidelines

Always refer to the manufacturer’s guidelines regarding lifespan. These guidelines help ensure compliance with safety regulations. Adhering to these recommendations provides extra assurance of protection. Always prioritize your safety by staying informed about the best practices for maintaining your gear.

Choosing Additional Accessories for Your Hard Hat

In many cases, hard hats can be equipped with additional accessories. These attachments enhance functionality and safety depending on the work environment. Knowing how to choose and install these accessories is essential.

Face Shields and Safety Glasses

Face shields and safety glasses are important accessories that add a layer of protection. They are particularly useful in industries where flying debris is common, such as construction.

When choosing a face shield, ensure it’s compatible with your hard hat model. Attach it according to the manufacturer’s instructions for optimal safety. Always keep your safety glasses clean; this will enhance visibility and performance on the job.

Hearing Protection

Hearing protection is another crucial accessory for some workplaces. Hard hats can often accommodate earmuffs or other hearing protection devices.

When selecting hearing protection, ensure it fits well with your hard hat shell. Proper adjustment is essential; like the hard hat itself, hearing protection must remain securely in place during labor.

Conclusion

Understanding how to assemble, maintain, and replace a hard hat is crucial. Safety gear plays a vital role in protecting workers from various hazards. Assembling a hard hat properly ensures a good fit and maximum protection. Regular maintenance and timely replacements are equally important. By following these guidelines, workers can safeguard their well-being effectively.

Training and safety protocols are essential in any work environment. Always ensure your hard hat fits correctly and is in excellent condition. Doing so not only fulfills safety requirements but also fosters a safe working atmosphere for all. Safety should never be compromised; prioritizing it leads to a culture of protection and prevention.